Nokia’s Head of Business Development talks about the benefits of deploying private 5G networks for companies.

Brazil – Head of Business Development in Verticals at Nokia Latin America, Renato Bueno also leads the Expansion Committee of the association ConectarAgro, whose main objective is to promote digital transformation in Brazilian agribusiness. In addition, he has more than 15 years of experience with startups and has held different positions in the Marketing sector.

In his conversation with topin, he discussed the advantages and the current panorama of the deployment of private 5G networks in industrial environments, how it is performed, what is necessary to make the transition from wired to wireless networks, 5G+ applications, and examples of sectors widely benefited by the fifth-generation connectivity technology.

topin: What are the advantages of deploying a 5G network in an industrial environment? What can this connectivity enable?

Renato Bueno: Industries, in their most varied segments, from the production of electronic devices to chemicals or food and beverages, have experienced an intense process of digital transformation. This digitalization aims at:

- Greater business efficiency: produce more with lower costs, less waste, and less consumption of energy and raw materials;

- Higher productivity: produce more with the same inputs;

- Greater agility: the ability to adapt to the new market and customer demands, increasing competitiveness;

- Enhanced decision-making capacity: the quality of information, in real time, with the aid of Artificial Intelligence (AI) and data analytics;

- Higher security: the security of professionals and assets is a non-negotiable aspect of the companies of the future;

- Sustainability: minimum environmental impact and neutral or even positive carbon footprint are now recurring demands of customers, society, market, and shareholders.

This digital revolution has been called Industry 4.0, and it will require a new platform for fast, ubiquitous, flexible, reliable, secure, and future-proof connectivity to connect machines, things, and people. The name of this platform is 5G; the current connectivity solutions meet specific demands but do not allow the necessary scale to enable all applications in the next ten years of the industry.

A study by Nokia Bell Labs, Nokia’s consulting, research, and development institute, estimates that industries that quickly adopt 5G+ – 5G-enabled digital applications – tend to increase their profitability by up to 11 times. And this profitability comes precisely from the impacts on the business by capturing new opportunities, producing at a lower cost, minimizing accident shutdowns, obtaining more speed in launching new products, etc.

topin: Many companies are still unfamiliar with mobile network technologies. How does installing a private 5G network work in an industrial environment?

Renato Bueno: Today, wireless connectivity in an industrial environment is synonymous with Wireless Fidelity (Wi-Fi). And this technology will remain relevant in the coming years, connecting people in rest and office environments or integrating legacy equipment and devices. Nonetheless, 5G will become the Industrial Internet of Things (IIoT) platform.

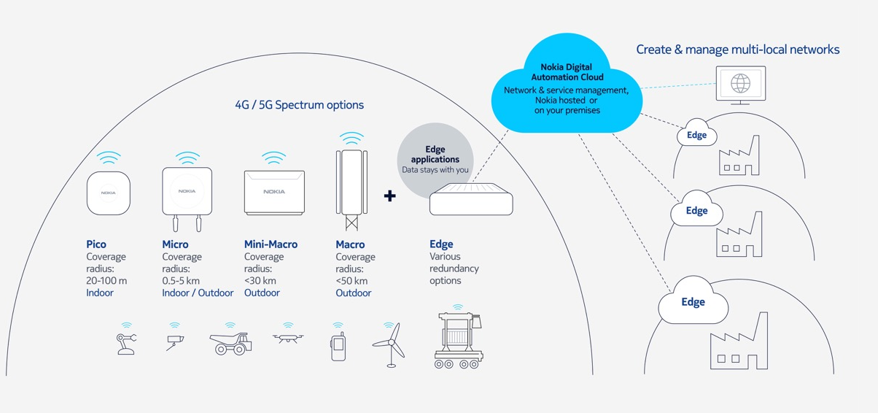

Nokia has developed a private networking platform called Nokia Digital Automation Cloud (NDAC), whose main objective is the simplicity of installation and operation. The idea is that professionals with experience managing a Wi-Fi network can operate a 5G network. The figure below presents the main components of this network:

- Local Edge server: installed locally, it ensures high availability and security for critical and low latency applications, allowing the connection with overall local and Cloud applications;

- Access points: 4G and 5G radio units with different capacities, according to coverage and capacity needs;

- Management platform: enables management and critical industry Service-Level Agreements (SLAs);

- Devices: gateways or devices – such as smartphones and sensors – that will connect workers, robots, and drones to their applications.

The process of launching a 5G network is quite simple and can be summarized as follows:

- Mapping needs: it is very important to build a roadmap of digitalization, a digital transformation plan that involves processes, people, skills, business, and technology. This first step, although not directly related to 5G technology, will bring clarity to the strategic objectives of the project – [according to] its financial and operational Key Performance Indicators (KPIs) – and will allow a correct scaling of the connectivity platform and its capacity, latency, and coverage requirements.

- Frequency definition: today, Brazil is privileged in Latin America regarding spectrum availability for private use. The Brazilian National Telecommunications Agency (ANATEL) has been doing a very consistent job in this sector. There are many possibilities, and we can assist in this understanding and planning.

- Network planning: proper radio frequency planning is critical to ensure the correct sizing of access points.

topin: Currently, it is very common for existing sensors and actuators to communicate with Programmable Logic Controllers (PLCs) via industrial cables or networks on the factory floor. After the introduction of 5G in this environment, how will these elements be integrated?

Renato Bueno: The traditional solution in an industrial environment is the construction of wired networks, which provide the reliability, capacity, and response time required for critical automation and robotics operations. Private 5G networks, with features such as Ultra-Reliable Low-Latency Communication (URLLC), will ensure a response time and reliability equivalent to those of wired networks but with the flexibility of a wireless one.

This allows cost savings in the construction of fixed infrastructure and flexibility and agility in the readjustment of production lines. Additionally, our solutions today support protocols typical of the industrial environment, such as Profinet or Ethercat, which can be transparently transported over the 5G network.

topin: We have seen announcements around the world about launches of industrial 5G networks. How mature is this technology, and how advanced is it in Brazil?

Renato Bueno: The concept of private 4G and 5G networks is old, having been first implemented in 2012 at the mining company Rio Tinto in Australia. It needed to manage six parallel networks, which were replaced by a private Long-Term Evolution (LTE) network. Since then, we have deployed more than 450 private networks worldwide – some of the largest networks in Latin America – in the energy, mining, floating production storage and offloading (FPSO), refineries, ports, and food and beverage sectors.

An extremely relevant case is the private network project implemented by Neoenergia in Atibaia, Brazil, a critical network for automation of the operation, maintenance, and control of the distribution network in the city. Although 5G is not yet available in the public networks of operato